PVC COMPOUND

PVC Compound is a versatile material widely used in applications like wires, cables, pipes, footwear, and automotive parts. It offers excellent insulation, durability, and resistance to chemicals and weathering. With customizable hardness, flexibility, and colors, PVC compounds can be tailored to meet specific industrial requirements. Their cost-effectiveness and ease of processing make them a preferred choice across multiple sectors. From construction to electrical and packaging, PVC compounds ensure consistent quality, strength, and long-lasting performance.

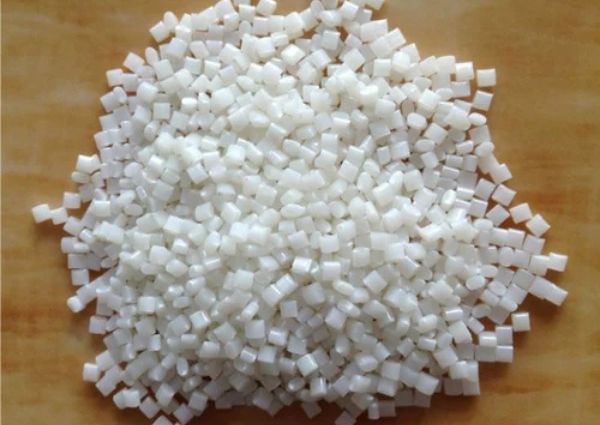

PP COMPOUND

TPE COMPOUND

SEBS COMPOUND

SEBS Compound (Styrene-Ethylene-Butylene-Styrene) is a high-performance thermoplastic elastomer offering exceptional elasticity, softness, and durability. It is widely used in applications requiring flexibility, such as footwear, medical devices, grips, and automotive interiors. SEBS compounds are resistant to weathering, UV light, and chemicals, making them suitable for outdoor and long-lasting applications. They can be processed easily using standard plastic methods while maintaining rubber-like properties.

EXTRUSION ABS

Extrusion ABS (Acrylonitrile Butadiene Styrene) is specially formulated for extrusion processes, offering high strength, impact resistance, and smooth surface quality. It is commonly used in automotive parts, construction profiles, household appliances, and consumer goods. Known for its excellent dimensional stability, extrusion ABS provides consistent output with superior finish and durability. It can be easily customized in color, texture, and additives to meet specific industrial needs.

METAL PLATING ABS

Metal Plating ABS is engineered for superior adhesion during electroplating, making it ideal for decorative and functional applications. It offers excellent surface finish, durability, and resistance to wear, making it popular in automotive, electronics, and household industries. With high impact strength and consistent plating performance, this compound ensures long-lasting metallic coatings that enhance both aesthetics and functionality. Metal Plating ABS is widely used for producing chrome-plated parts, handles, trims, and emblems

SCRATCH-RESISTANT ABS

Scratch-Resistant ABS is a specially developed compound designed to maintain surface appearance even in high-contact applications. It combines the toughness of ABS with advanced scratch-resistant additives, offering superior durability and aesthetics. This compound is ideal for automotive interiors, electronics, home appliances, and consumer goods where surface protection is essential. It provides long-lasting gloss, impact strength, and chemical resistance while reducing visible wear and tear.

HEAT RESISTANT ABS

Heat-Resistant ABS is designed to withstand elevated temperatures without losing its structural integrity or performance. It is widely used in automotive components, electronics, appliances, and industrial parts where exposure to heat is common. This compound offers superior dimensional stability, toughness, and resistance to warping under thermal stress. With customizable grades, Heat-Resistant ABS ensures reliability in demanding environments.

FLAME RETARDANT ABS

Flame Retardant ABS is a specialized compound formulated to reduce flammability and meet strict fire safety standards. It retains the toughness, processability, and aesthetic qualities of ABS while providing enhanced resistance to ignition and flame spread. Widely used in electrical appliances, electronics housings, automotive parts, and construction, Flame Retardant ABS ensures both safety and performance. It is available in halogen-free and eco-friendly options to meet environmental standards.

ASA ABS

ASA ABS (Acrylonitrile Styrene Acrylate + ABS) is a weather-resistant compound that combines the strength of ABS with the superior outdoor durability of ASA. It offers excellent UV resistance, color stability, and toughness, making it ideal for automotive exteriors, outdoor furniture, roofing, and construction materials. ASA ABS maintains gloss, color, and strength even in harsh weather conditions, ensuring long-lasting performance. It is easy to process, customizable, and recyclable, making it both versatile and eco-friendly.